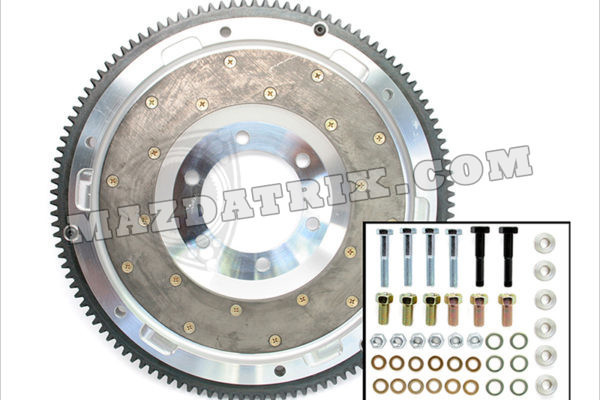

FLYWHEEL HARDWARE, ALUMINUM 83-92 NON TURBO

Aluminum Flywheel Hardware Kit, 83-92 Non Turbo (nuts and bolts)

Fits Racing Beat Flywheels only

| SKU: | 95368 |

FLYWHEEL HARDWARE, ALUMINUM 83-92 NON TURBO

This kit contains the required hardware to mount a Racing Beat Aluminum Flywheel to any 1983-92 12A or 13B non-turbo engine. The kit also includes the small spacers required for mating the pressure plate to the Racing Beat flywheel. Each kits includes mounting bolts, nuts, washers and instructions.

$52.39

Related Products:

-

FLYWHEEL STOPPER TOOL, ALL Non-Turbo diameter flywheels

Flywheel Stopper Tool, All Non-Turbo diameter flywheels (Except RX-8’s)

Flywheel stopper makes getting the flywheel / counterweight nut off a LOT easier.

For flywheels 11 3/4″ diameter.SKU: 49-220NT Manufacturer SKU: 49-220NT -

REAR COUNTERWEIGHT, 13B 74-85

Rear Counterweight, 13B 74-85

SKU: 11-751A-1029 Manufacturer SKU: 1029-11-751A -

-

FLYWHEEL ALUMINUM, 83-92 N/A NO COUNTERWEIGHT

Aluminum Flywheel, 83-92 Non-Turbo – Requires Counterweight

Applications

This RX-7 flywheel is best-suited for use on high performance street, autocross, track, and racing applications. The performance benefits of an aluminum flywheel are well-established: improved throttle response, quicker engine revving, and improved shifting efficiency.Although aluminum Flywheels can certainly be used for daily-driven RX-7 street vehicles, the modest torque output of the earlier 13B engine combined with the reduced mass of the aluminum flywheel will require a bit more technique during clutch engagement when starting the vehicle from a standing start. This is especially true when using a higher clamping force pressure plate and more aggressive clutch disc. If this is a concern, you may want to consider our Lightweight Steel RX-7 Flywheel as an alternative.

Precision Machining

The RX-7 aluminum flywheel kit both reduces the flywheel weight up to 55% and reduces the flywheel inertia up to 80%, as compared to the Mazda Factory OEM cast iron component. Precision CNC machined from 6061-T6 aluminum, our flywheel assembly is mated to the Mazda OEM ring gear and finished with an extremely durable, and easily replaceable clutch disc friction plate. Each friction plate is machined from A-36 steel and hardened using a ferritic carburizing heat-treating process, creating an extremely durable clutch disc contact surface. The friction plate is retained to the aluminum flywheel unit using aircraft-spec bolts and lightweight nuts. The ring gear is thermally-mated to the flywheel and bolted in place for added security to prevent slippage during engagement of the starter motor.Weight Comparison

1981-85 RX-7 Stock Flywheel: 23 lbs

1986-88 RX-7 Stock Flywheel: 24 lbs

1989-92 RX-7 Stock Flywheel: 22 lbs

Aluminum Flywheel: 12 lbs (including required counterweight)Retaining Critical Engine Balance

The installation of an aftermarket flywheel requires the use of a Mazda rear counterweight unit to ensure critical balance of the internal rotating assembly (engine rotors). As produced by Mazda, the original stock rotary flywheel features a pronounced balancing mass included in the flywheel casting. This balancing mass, combined with the stock front counterweight unit, provides the correct balance required for the optimal rotational operation of the engine rotors.To allow an aftermarket aluminum flywheel to be used on several different rotary engine applications, this balancing mass is eliminated from the design of the rotary flywheel. However, this critical balancing mass must be replaced with an alternative balance weight or risk severe engine damage due to an “unbalanced” engine. A convenient alternative is to install an appropriate rear counterweight from an automatic transmission-equipped RX-7. We offer this counterweight separately if needed.

Rear Counterweight (Required)

All aftermarket flywheels require the use of an automatic transmission rear counterweight for correct operation.Installation Hardware

Our Flywheel kits include the flywheel unit and the appropriate mounting hardware, which includes the appropriate tensile-strength hardware to attach the pressure plate to the flywheel. DO NOT use other aftermarket flywheel mounting kits with our flywheels.We strongly recommend replacing the throwout bearing during any clutch work to ensure trouble free performance. Also, we recommend replacing the transmission front and rear seal kit when re-installing the transmission to reduce the possibility of leakage.

Safety Warning

None of the flywheel or clutch components shown in this site should ever be allowed to exceed 10,500 RPM under any condition. This same RPM limit applies to stock components. You must use an engine RPM-limiter to prevent excessive RPM. If your engine is capable of exceeding 8,500 RPM you must install a transmission scatter shield, or ballistic blanket. Failure to implement the above may result in serious injury or even death.SKU: 11434 -

REAR COUNTERWEIGHT, 13B 86-88

Rear Counterweight, 13B 86-88

SKU: 11-52X0-N3Y8 Manufacturer SKU: N3Y8-11-52X -

CLUTCH KIT STAGE 1, 83-92 NON TURBO

Clutch Kit Stage 1, 83-92 Non Turbo

Street/Strip performanceSKU: 10806 Manufacturer SKU: 10806